-

Welcome visitor you can login or create an account.

WINTAI M881 Basic Type 3D Wheel Alignment System

WINTAI M881 Basic Type 3D Wheel Alignment System

WINTAI M881 Basic Type 3D Wheel Alignment System

Feature:

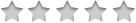

1. Chinese Windows OS, operation process can be easily guided by "Next step" instruction.

2. Exceed 20,000 database around the world and with a lifetime update service.

3. Repeat measurement accuracy is ±0.03,which be a world's leading level.

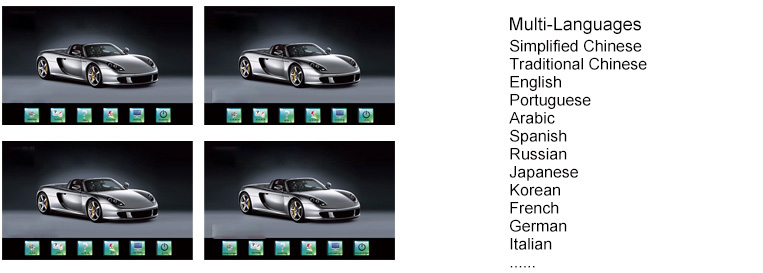

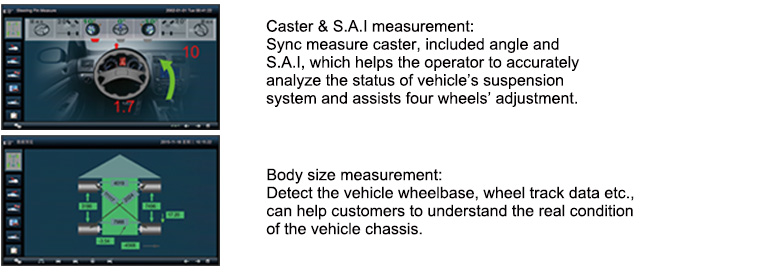

4. Measurement Angle: Toe, Camber, Caster, S.A.I, thrust angle, Setback angle, Max turning angle, Wheel tread, Wheel base, Wheel rolling radius.

5. Android cell phone and laptop are supported to show the vehicle measurement data, more convenient for operator.

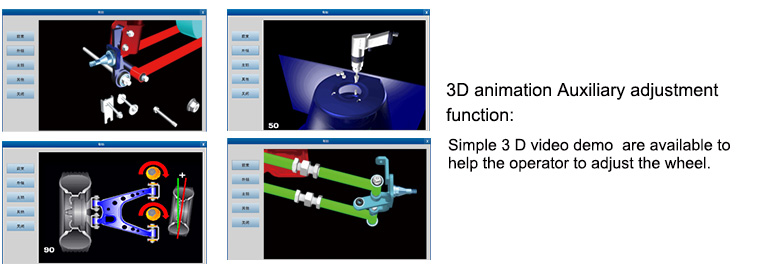

6. Humanized software design, animation video can be used to help technician more quickly complete the operation.

7. Ultra-low chassis and refit vehicle—Volks Wagen and Audi, XLWB and with ESP function vehicle are also can be measured.

8. Secondary jack-up function, which can be used to more conveniently help technician adjust Camber.

Standard configuration:

. Options: The wheel alignment software could be installed in the Table PC with Android system. Clients can long-distance operate the wheel alignment measurement

through Bluetooth.

. Parking assistant camera function: independent web camera can guide the vehicle pack in the specific location.

. Apply high strength plastic target, which is lighter, thinner and stronger.

. Fast installation, suitable for all rims between 12”-23” . Double chuck, which can install both on iron and aluminum wheel hub.

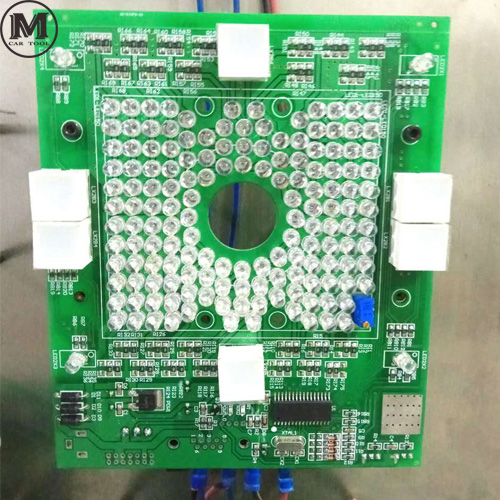

. 5 million high definition camera: it can also assure accurate alignment measurement when target plates get smaller. Intelligent LED navigation system: the operator doesn’t need to check the screen for the instruction of intelligent LED navigation system and can easily complete wheel alignment operation.

Technical parameters:

|

ITEMS |

Front wheel measurement precision |

Front wheel measurement range |

Rear wheel measurement precision |

Rear wheel measurement range |

|

TOE |

±0.02 |

±20° |

±0.02 |

±20° |

|

CAMBER |

±0.02 |

±15° |

±0.02 |

±15° |

|

S.A.I |

±0.02 |

±26° |

x |

x |

|

CASTER |

±0.02 |

±26° |

x |

x |

|

THRUST ANGLE |

x |

x |

±0.02 |

±5° |

Write a review

Note: HTML is not translated!