-

Welcome visitor you can login or create an account.

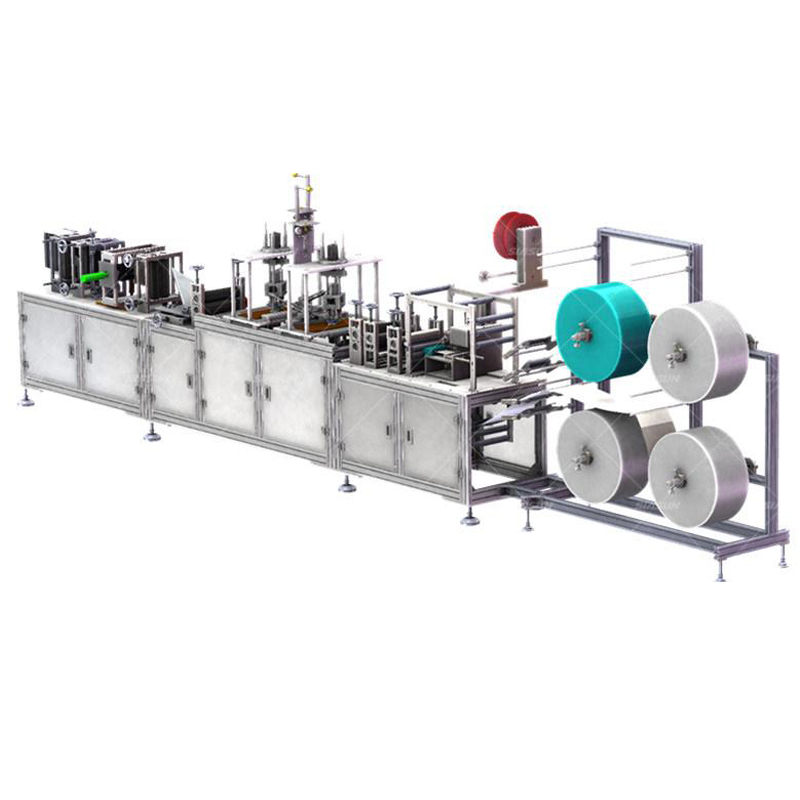

KN95 Face Mask Production Line

KN95 Face Mask Production Line

WHATSAPP/WECHAT: 008618813968941

Introduction:

The production line can be fully automated from non-woven rolls to end-product masks. Equipment units include:

Coil raw material feeding unit, middle and inner layer pre-feeding unit, nose clip feeding unit, mask contour welding

Unit, code printing unit, ear band feeding unit, ear band welding unit, mask folding unit, cutting edge cutting unit, etc.

Features:

1. This machine is compatible to produce a variety of masks.

2. The use of intelligent tension control system can ensure a more balanced raw material feeding.

3. Intelligent control makes sure real-time monitoring of various performance indicators of the production line, good stability.

4. Coordinated movement of each unit makes sure continuous production ,

5. Intelligent detection, fault early warning, easy operation and maintenance.

6. Nice appearance, durable.

Parameters:

Machine size:(L×W×H ):see drawing

Color:white

Voltage:AC220V,50HZ/60HZ,1P

Production efficiency:30-45PCS/min:13KW

Machine Weight:≤5000kg, Floor Capacity≤500kg/m2

Air Input:0.5-0.7Mpa,300L/min

Working Environment:temperature 10-35 °c,humidity 5-35%HR, Non-flammable,no corrosive gas,No dust(Cleanliness of not less than 100,000)

Symmetry of fold:+/-2mm

Equipment failure rate:2%(Refers to faults caused by the equipment itself)

Write a review

Note: HTML is not translated!